We are going to illustrate a real case of two FANUC Type A06B-0157-B075 # 7008 servomotors referring to preventive and corrective maintenance from the same company.

You will see the originated differences photographically, from the same Fanuc servomotor model, one focused on preventive maintenance and the other on corrective.

Maintenance is an essential task for the correct operation of any company, especially one that depends on servomotor equipment, AC&DC motors. We must never neglect it, because in the long term it can save us a lot of money.

Differences between preventive and corrective maintenance

Preventive maintenance is one that focuses on ensuring the good condition of the equipment based on a work plan that prevents breakdowns from occurring. They are tasks such as changing the oil of a machine, proper cleaning or inspections of the installation. According to experts, this is the most efficient maintenance to guarantee the good condition of the equipment at the lowest cost. It is carried out routinely, in order to extend the useful life of the machines as much as possible.

Corrective maintenance, which does not require any planning, just requires dealing with breakdowns day by day as they arise.

Following this strategy, we wait for the asset to fail and then we repair or replace the equipment, which produces significant downtime due to a lack of preparation.

This is not the optimum strategy when the downtime cost is greater than the maintenance cost.

With a system of preventive maintenance, the maintenance is predictable and allows for preparation before an unexpected and costly downtime scenario occurs.

Preventive maintenance of a Fanuc servomotor

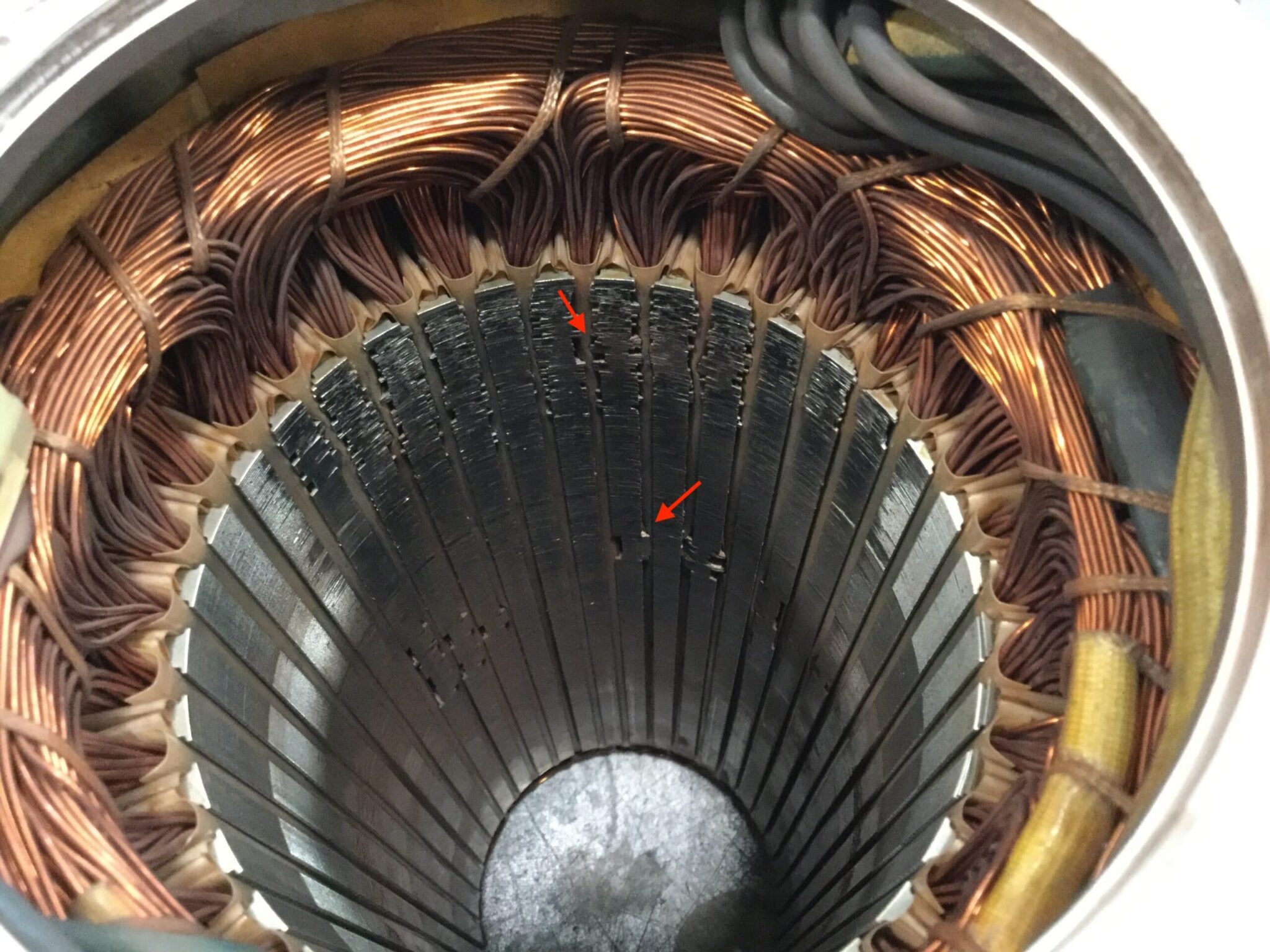

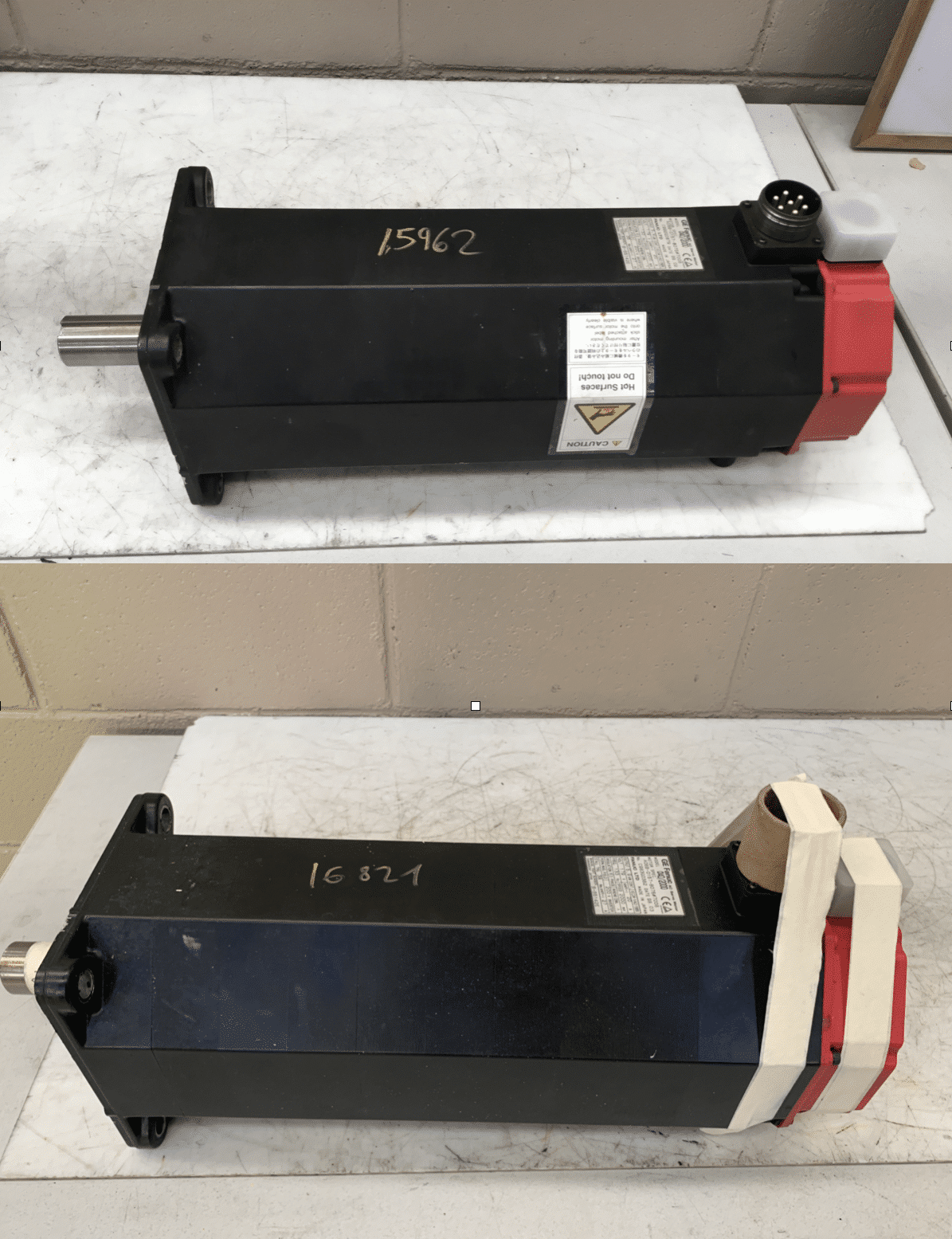

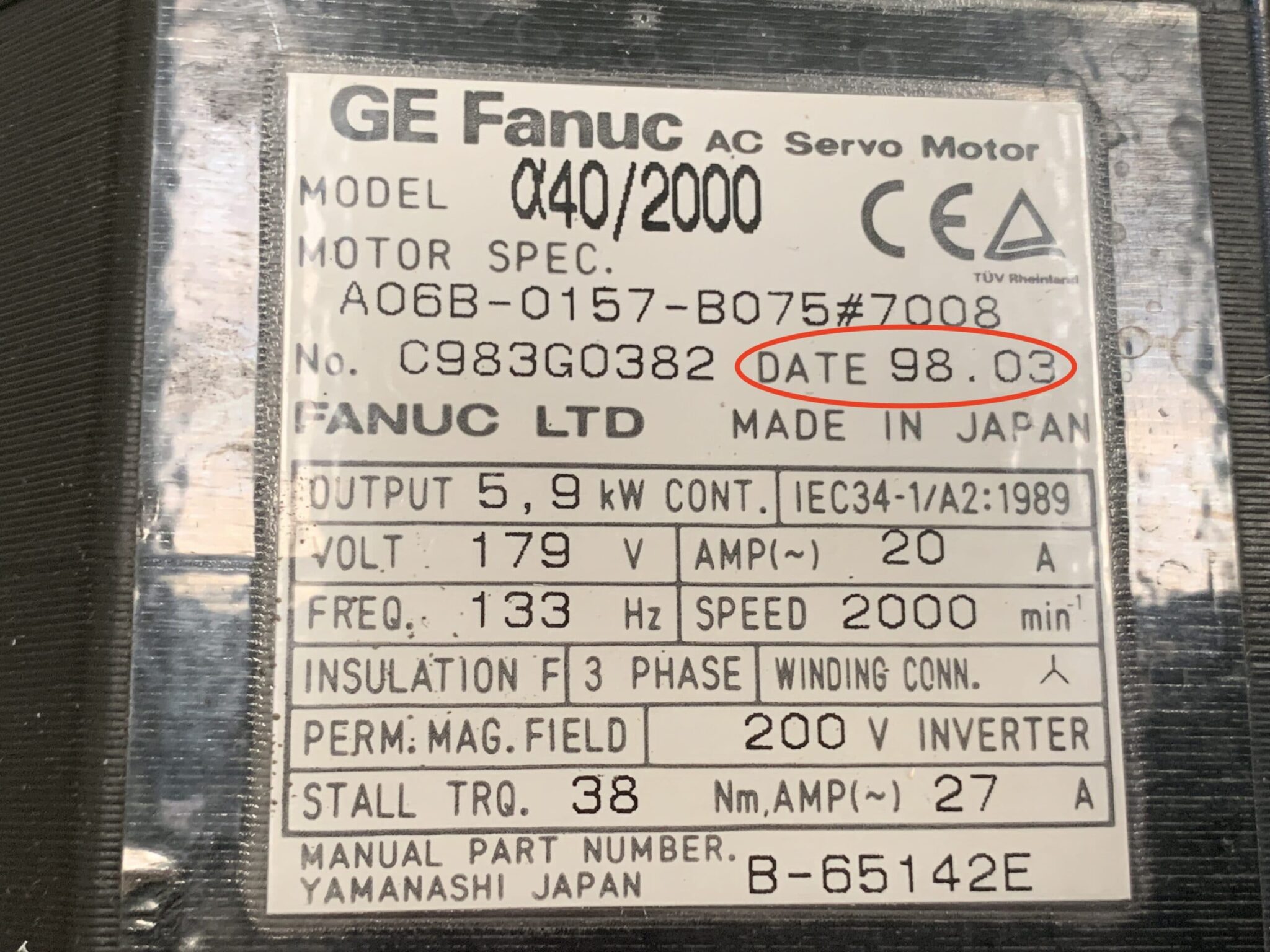

Introducing a Fanuc servomotor that has worked 24 hours a day, seven days a week since 1998. (see picture 1)

- Picture 1

The following photos show the good condition of the servomotor, this being its first repair after 22 years of work.

This demonstrates the importance of managing an adequate technical shutdown in a servomotor, programmed by the Maintenance Department.

Corrective maintenance of a Fanuc servomotor

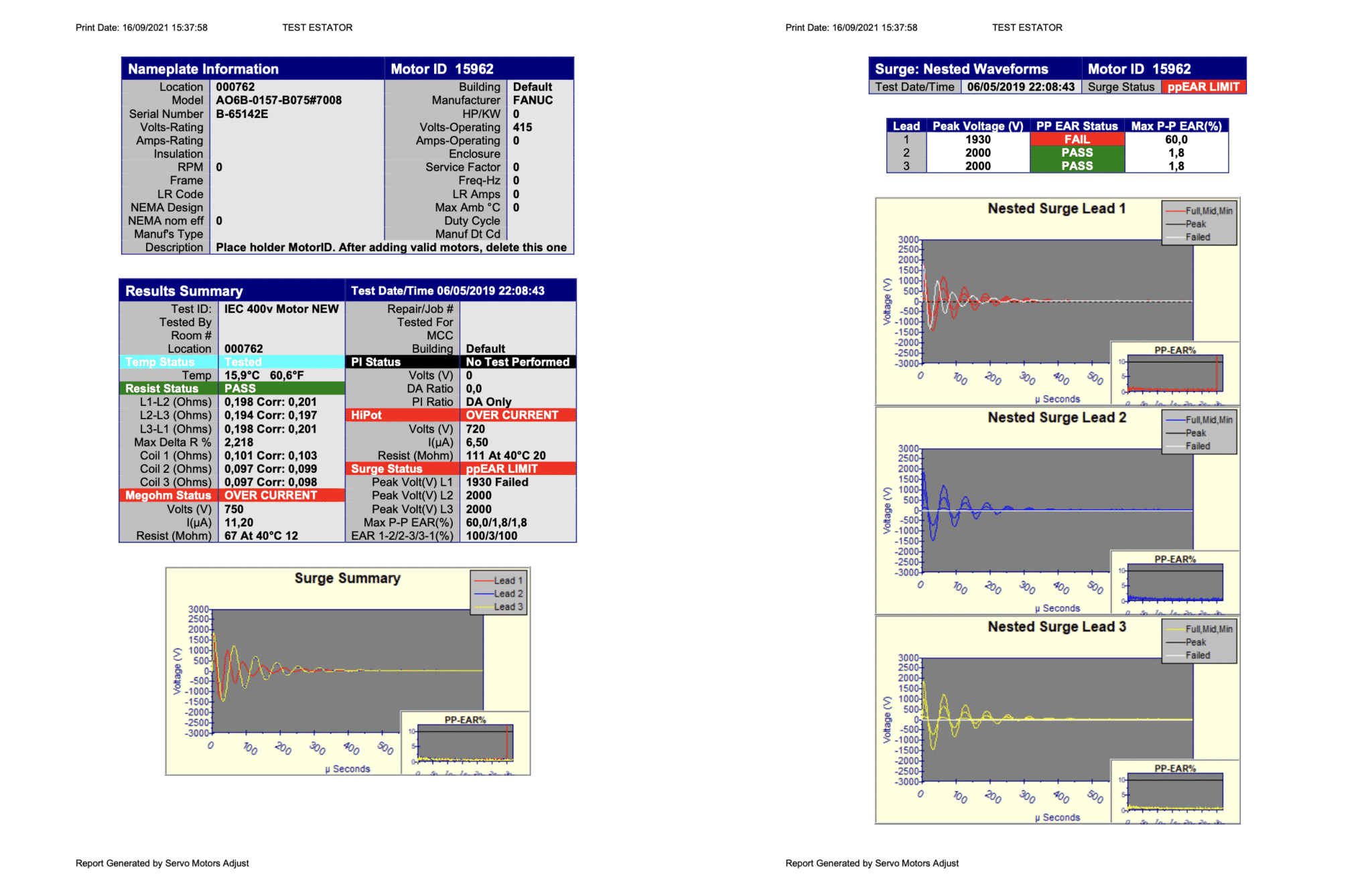

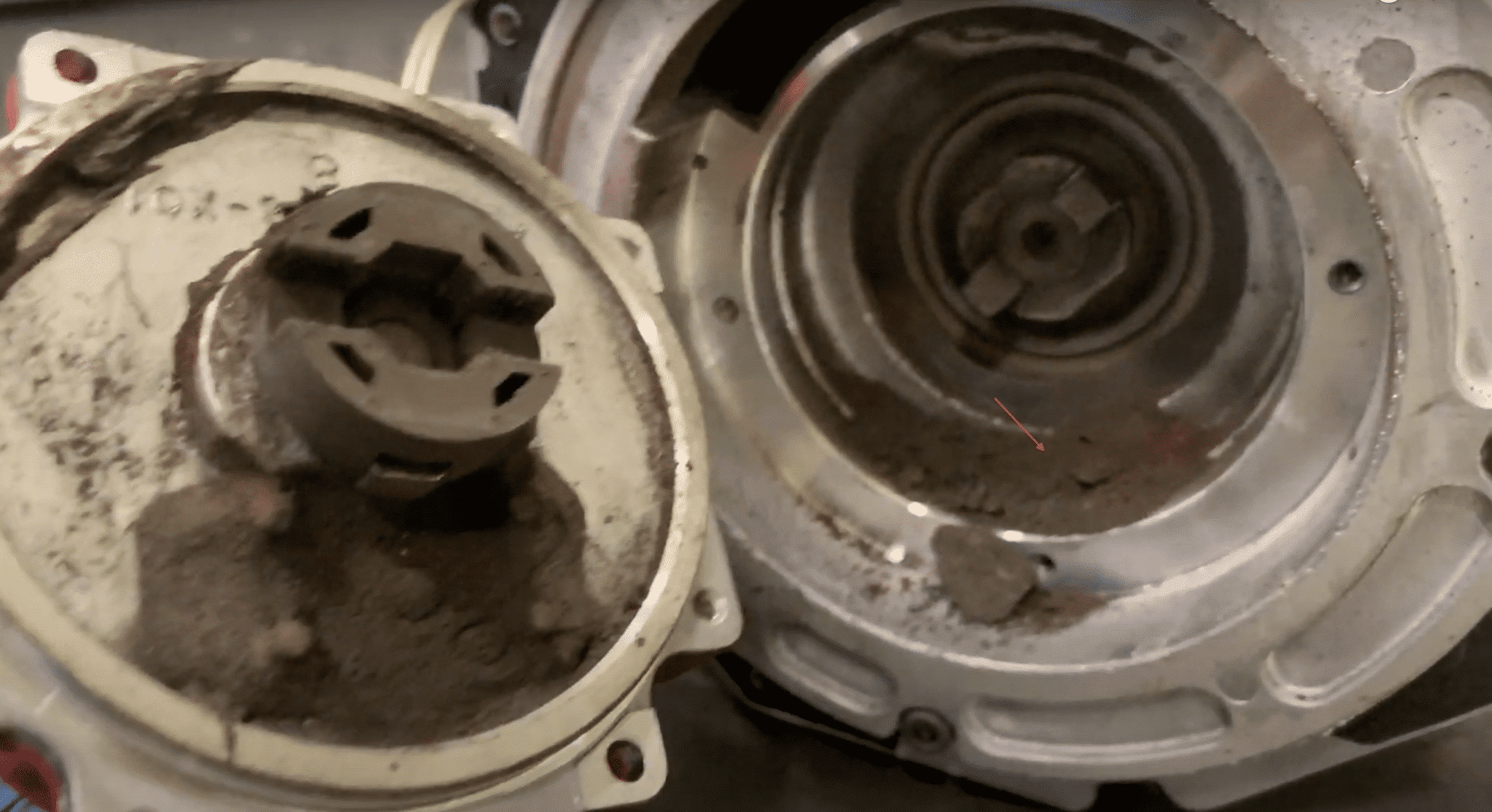

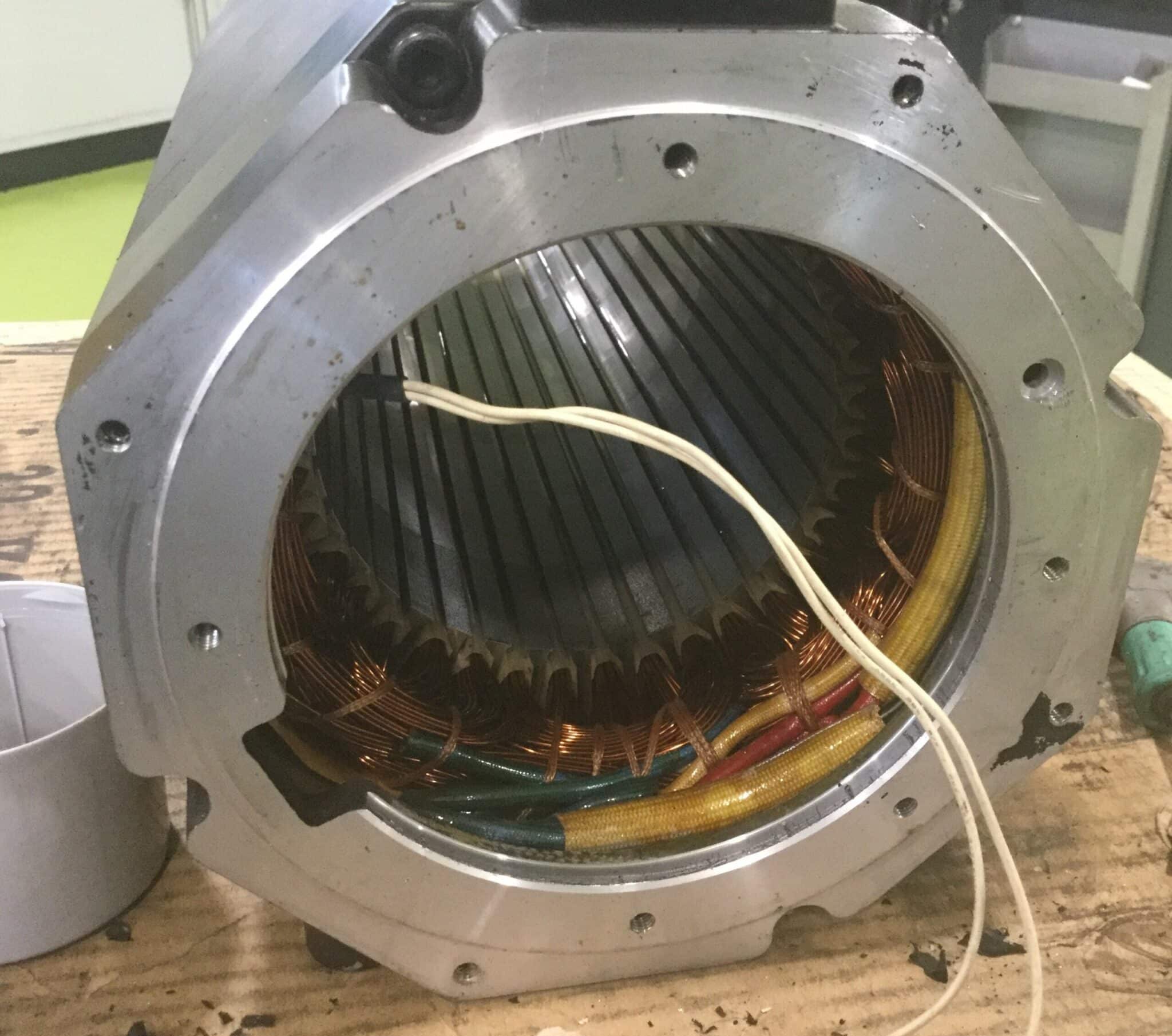

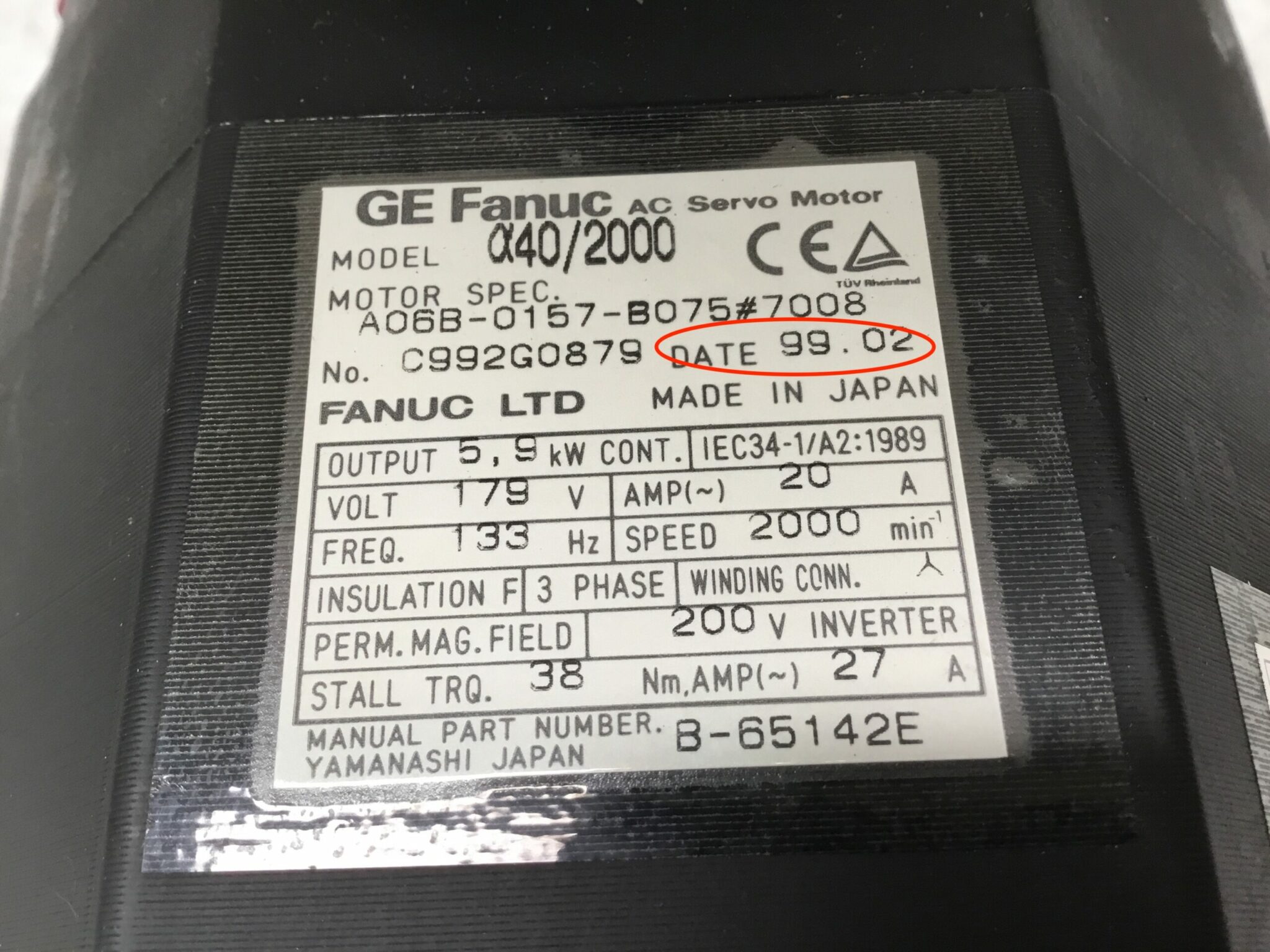

Introducing a Fanuc servomotor that has worked 24 hours a day, seven days a week since 1999. (see picture 2)

- Picture 2

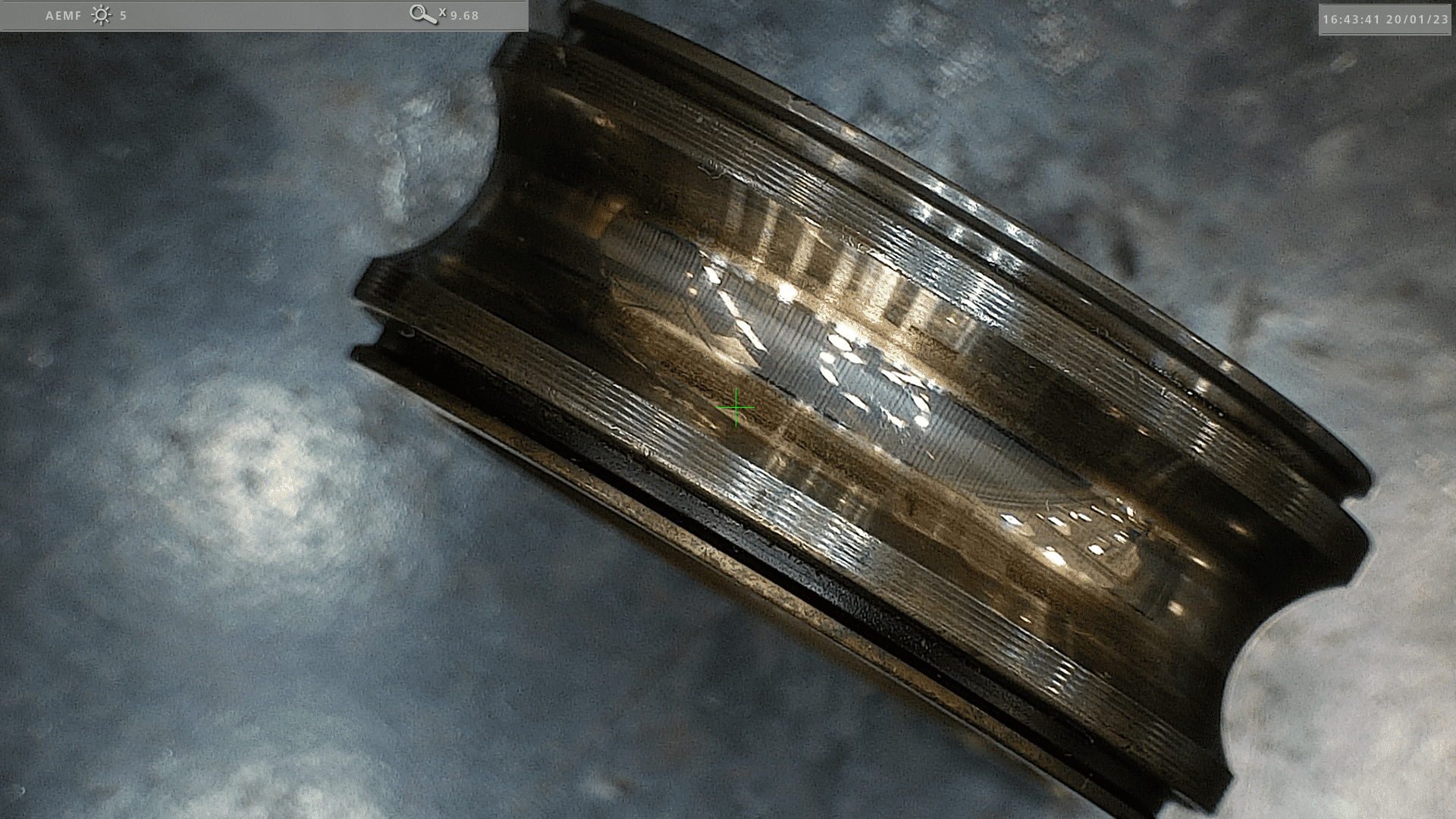

In the following images we can see: 1) the poor condition of the stator, 2) the front bearing has rotated on the shaft (its seat) as a consequence of the sliding or micro-movement of the inner ring, producing great wear in the area, (housing diameter out of tolerance); 3) The rear cover and the adjusting washer, as a consequence of the sliding of the bearing, cause small particles of material to come off, which will act as abrasive particles increasing the wear in the housing. These small abrasive particles have affected the encoder.