Both the proper working of the motor and the driver is important for the correct functioning of a servo system. Therefore we must pay attention to the electronic equipment, know what conditions affect them negatively and try to avoid them or solve them.

Factors that affect our electronic equipment negatively

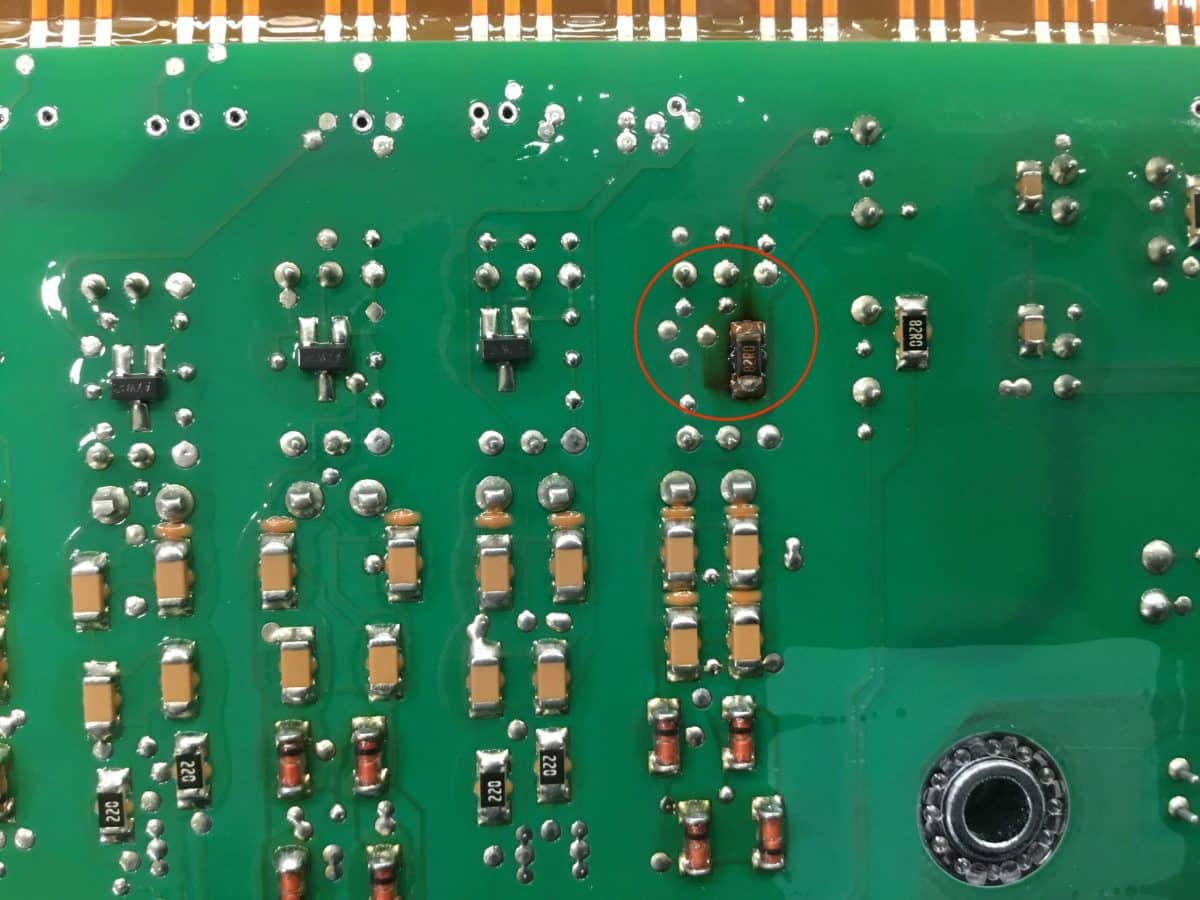

Changes in temperature, dust, humidity and the total number of working hours affect both the components and the connections, deteriorating them. This causes an increase in the resistance in the electrical flow that can lead to incorrect readings and produce overheating.

- The changes in temperature and in particular overheating cause the materials to expand and contract. This can weaken the connections and the welding.

- The accumulation of dust causes the temperature to increase, particularly reducing the performance of the fan and can even block it. In addition, the dust makes a film over the components and the connections that can reduce the performance of the equipment and in the long term can produce intermittent failures or false contacts.

- In places with a high level of humidity, condensation inside the equipment can happen that may cause component corrosion and finally produce short-circuits between two tracks, connectors or adjacent chips, causing failures.

The total number of working hours causes the wear and tear of some pieces, in particular, the transistors and power sources. If the power source does not work properly it must be replaced as soon as possible to avoid more serious damage in the equipment.

How to protect the equipment

- Maintain the room temperature between 20ºC and 25ºC. If, for example, the working temperature of the variable frequency drives (VFD) increases by 15ºC, its working life will be three times shorter.

- Avoid dust. As we have already mention, the accumulation of dust inside the equipment can cause the bad functioning of the motors and lead to downtime.

- The humidity must be between 40% and 55%.This humidity range is high enough to prevent static electricity and low enough to prevent condensation.

- Placing the equipment in racks or in air-conditioned rooms will help to make the equipment’s working life longer and minimalize its maintenance. This option is not always possible, but what we can do is keep the drives and controllers as clean as possible.

To keep them clean it is not enough to simply remove the dust or dirt from the outer surfaces, it is necessary to remove the cover and clean them on the inside. In the market there exist a wide range of products, but if we are not sure how and where to apply them the best thing is to clean them with compressed air sprays and avoid liquids and products that can damage instead of help.

If in doubt, the best option is to contact a professional, who will carry out proper maintenance of components, connections and software in addition to cleaning.