Electrical erosion in bearings

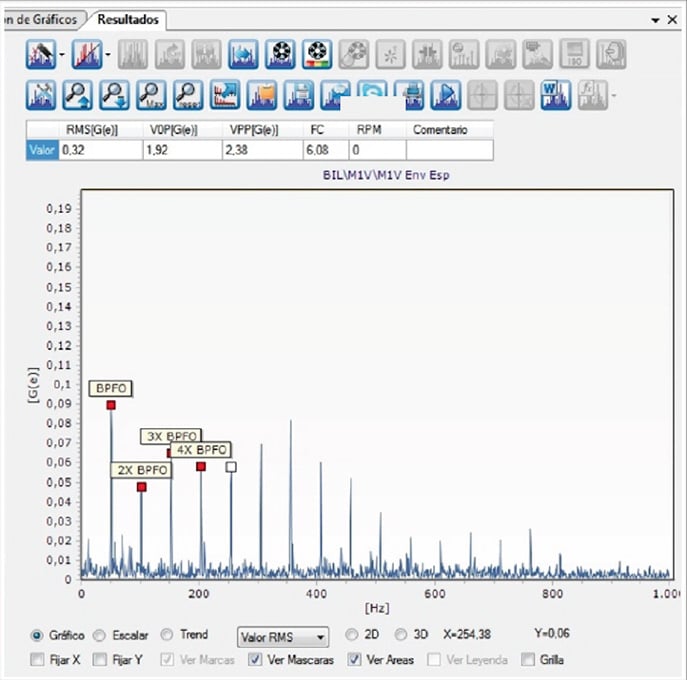

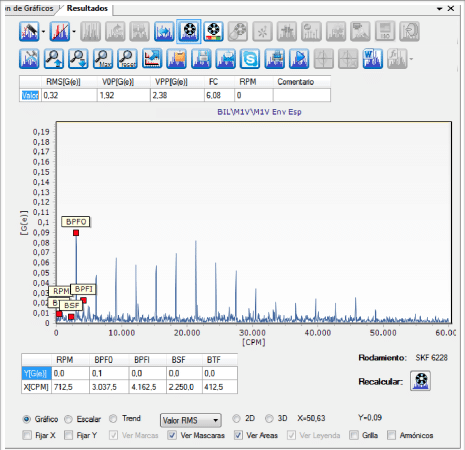

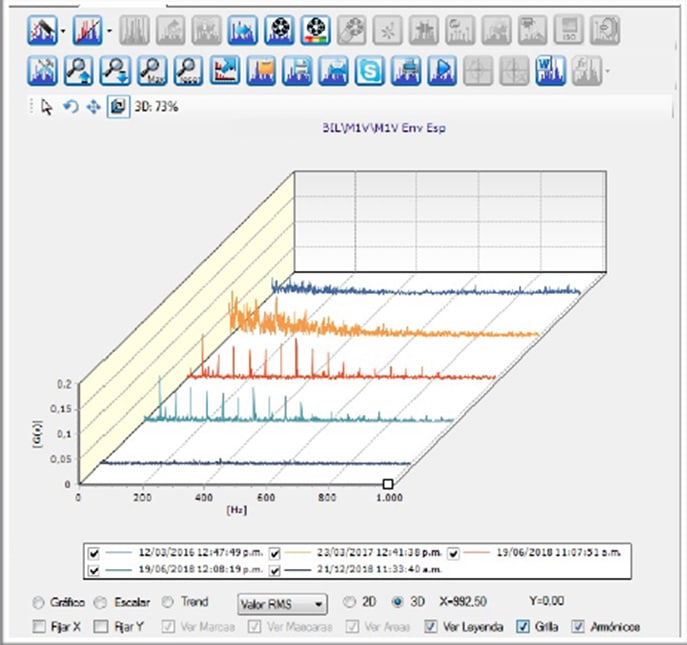

When a bearing produces unwanted vibrations, there is an important defect in its component(s). These vibrations lead to the corresponding (BPFO-BPFI-BSSF-FTF) defect frequencies in the spectrum, usually appearing first in the harmonics. These harmonics are the ones that inform us of the bearing’s condition and tell us if it needs to be replaced.

Once the bearing has been changed we will analyse the defect and how serious it was. By doing this corrective measures can be applied so that it does not happen again.

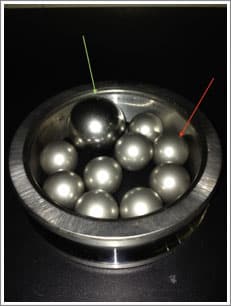

Bearing fluting

In this bearing in particular you can see fluting – this is the damage in side the bearing caused by the electrical current flow, which produces marks in the outer race or groove.

In picture 1 you can see the electrical erosion in the outer race.

In picture 2 you can see the characteristic matte effect of the bearings with electrical erosion comparing them with one without erosion that is shinier ( green arrow ).

Picture 1

Picture 2

How to detect electrical erosion in bearings?

This can be seen with the appearance of failure frequencies in the outer race or groove (BPFO) and its low frequency harmonics.

The electrical current flow is produced when the shaft voltages are discharged to earth through the bearing. This leads to electrical erosion, deterioration of the lubricant and the bearing failure.

In the following pictures you can see the BPFO, 2xBPFO, 3xBPFO and spaced out to BPFO.

ELECTRICAL CURRENT FLOW DETECTOR

In order to detect the current flow we recommend this simple tool: SKF TKED1.

HOW TO AVOID THE ELECTRIC CURRENT FLOW

Basically, we have two options to prevent the electrical current from flowing through the bearings:

- Use insulated bearings. These bearings are designed to avoid the electrical current flow.

- Place a shaft grounding ring. This ring is placed in the shaft, whenever it is conductive and prevents the electrical damage in the bearings by safely grounding the shaft’s harmful currents.

By applying one of these two solutions we will achieve better working conditions for the bearings and this means that they will have a longer useful live and we will avoid unexpected production downtimes.