Choosing a good servomotors service partner

Servomotors are increasingly more common in industry nowadays, where precision (speed, precision, and torque control) is needed.

Servomotors can be found in almost all industries, machine tools, robots, and any place where there is an automated process. That is why it is essential to count on a trusted servomotors service partner to avoid costly downtimes.

We received a Control techniques servomotor, from a new customer.

The servomotor had already been repaired by another company, and in less than a year the encoder showed an error again. The customer did not understand that in less than a year, their servomotor had broken down again, (Encoder error: red label)

-

Servomotor analysis

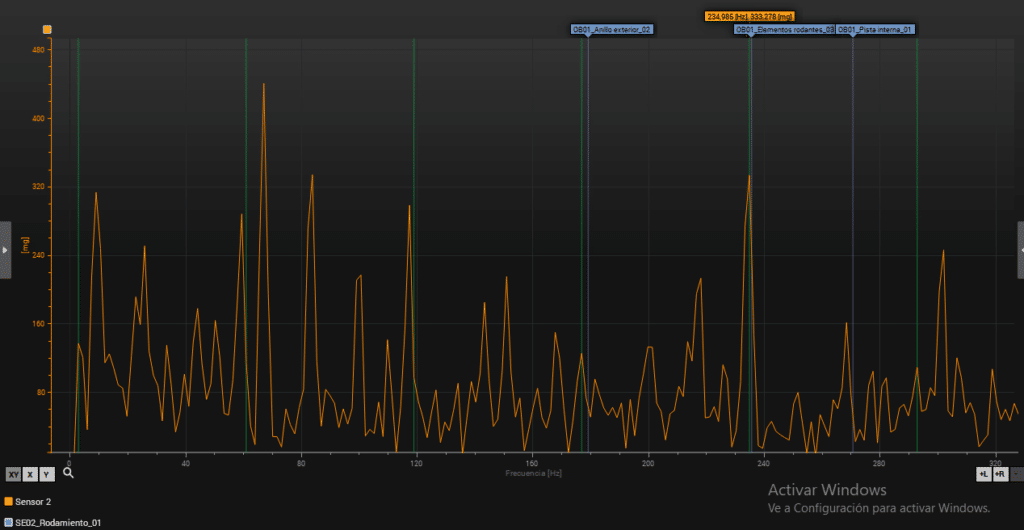

After checking the servomotor’s functioning, prior to disassembly, our technicians detect a problem in the vibration control in the front where the bearing is located.

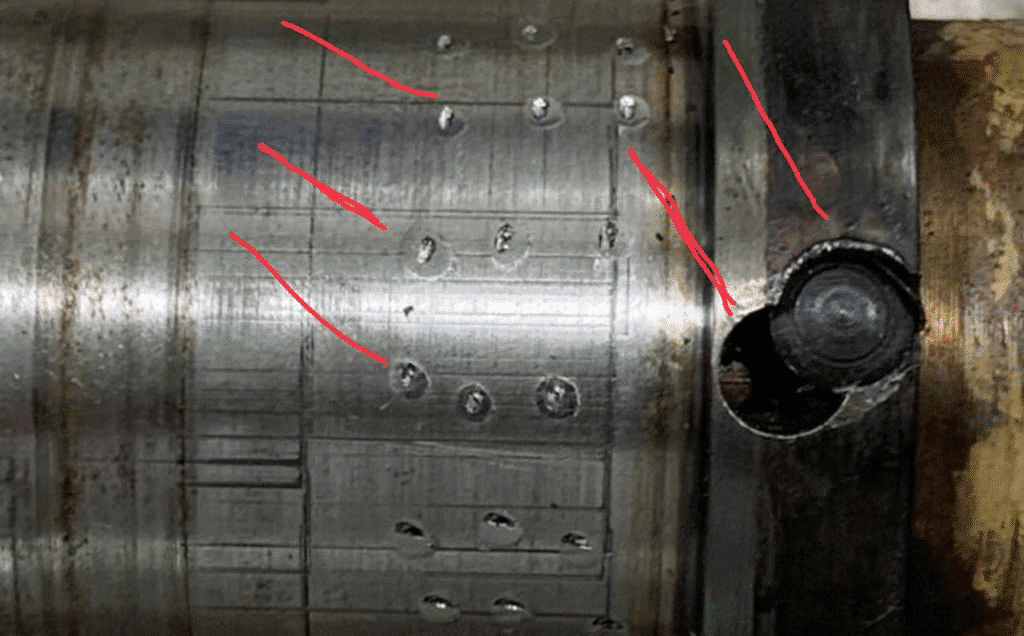

Once disassembled, we can see the state in which the servomotor is.

In the following pictures you can see the shaft (rotor) in front bearing housing, the punch marcs, this are produced by a punch. Which shows that it had been previously repaired by another company without a reliable, quality process.

At Servo Motors Adjust, we have achieved EASA Accreditation to ensure the efficiency and reliability of the electric motors we repair. In addition, we have successfully demonstrated through a third-party independent audit that we follow best practices to offer quality electromechanical repairs that maintain or improve the efficiency and reliability of the electric motor.

-

The solutions would be:

1.- Buy a new shaft (rotor) from the manufacturer (OEM) but in many cases they are out of stock as the motors are obsolete.

2.- Disassemble the rotor shaft

– Make a new shaft

– Assemble it on the rotor again

– Equilibrate the shaft mounted on the rotor.

-

Servomotor assembly and test

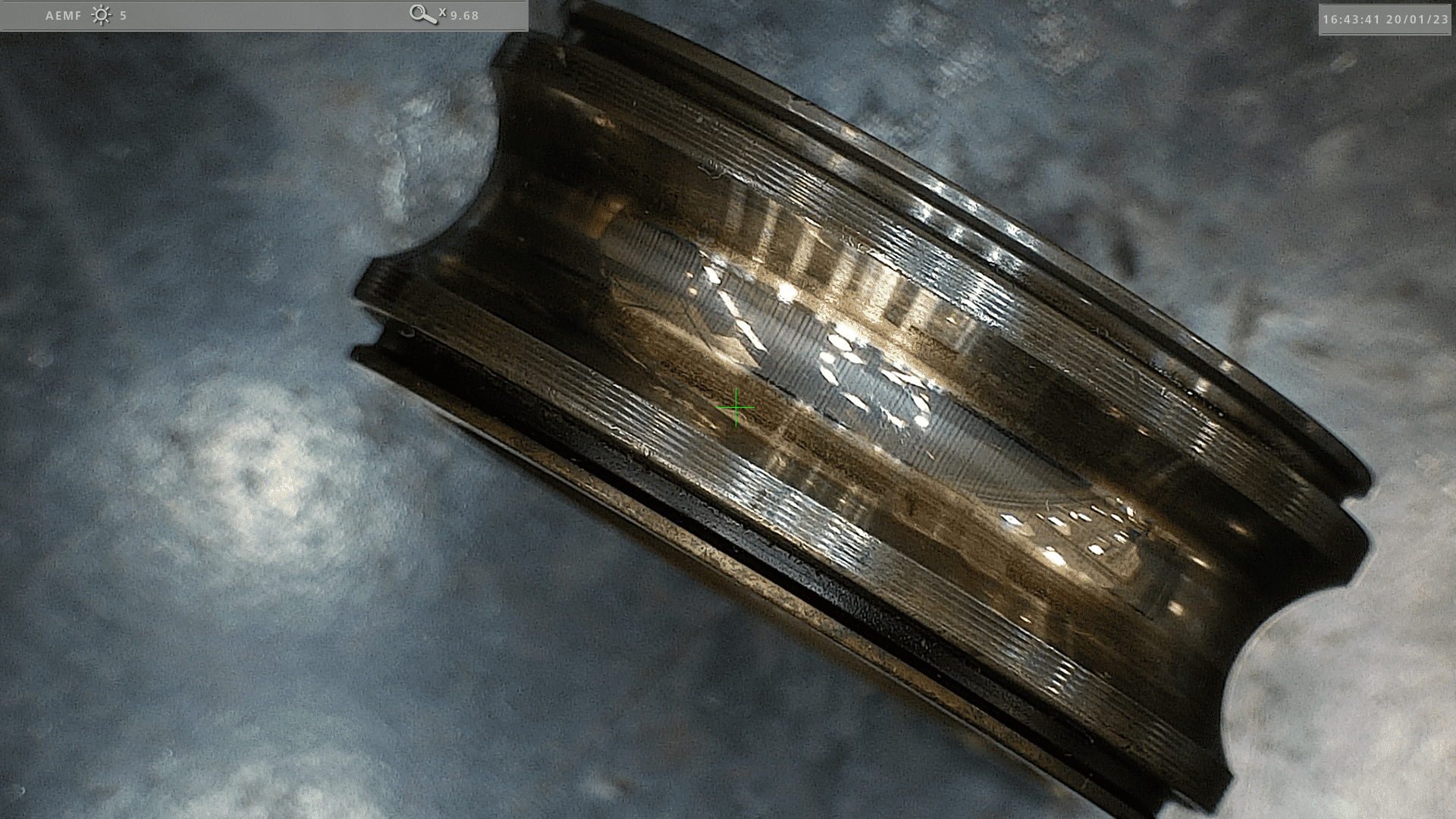

In the pictures below you can see the new shaft, before being mounted on the rotor, which was the solution decided on by our technicians.

Once the servomotor has been assembled, with the new shaft (rotor) and with new bearings, seal oil and the encoder previously analyzed. We move on to the final test checking that it rotates at speed and in position perfectly.

“The best preparation for good work tomorrow is to do good work today”.

Elbert Hubbard