The importance of giving a second life to your systems

Concepts such as energy efficiency, sustainability, the IoT or industry 4.0 are the order of the day and are no longer a novelty. However, what is different are the different ways in which each company can carry out projects that contribute to being more energy efficient and at the same time more sustainable.

In fact, one of the main challenges for the industry continues to be becoming more sustainable. According to the European Environmental Agency, in recent years there have been advances, such as greater rigour in environmental regulations, improvements in energy efficiency and, in general, a tendency for European industry to abandon some types of heavier and more polluting manufacturing or to participate in voluntary programs to reduce their environmental impact. But the industry continues to generate too high a level of pollution and waste, especially in sectors such as energy, fashion or transport.

Sustainable Development Goals

At Servo Motors Adjust we believe that each company must periodically carry out a process of internal self-analysis and reflection to assess what results the actions it has carried out in this regard are having and, above all, think about what other aspects can be improved to increase energy efficiency, like reducing your carbon footprint, for example. Let’s not forget that the energy outlook in Europe is not very favourable for companies, with rising prices and the shadow of supply shortages still a reality.

How do we contribute?

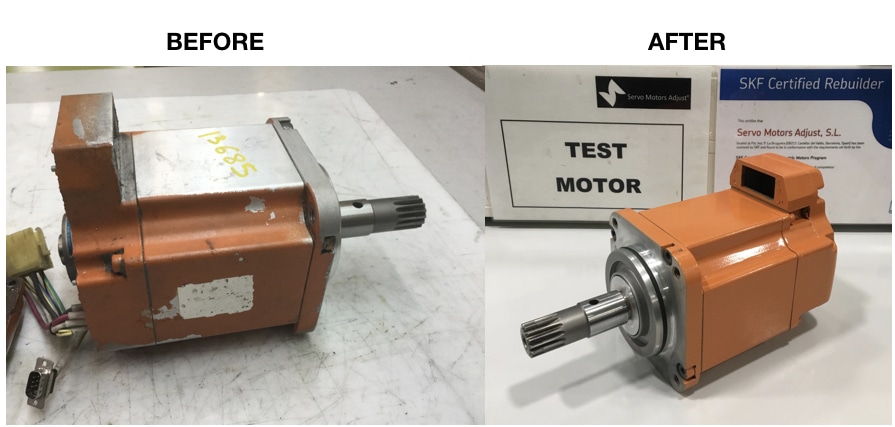

In addition to dedicating ourselves to the repair of servomotors, drivers and hybrid and electric batteries, we can provide solutions and improve the profitability of our clients’ equipment. Thanks to proper repair and maintenance, we give a second life to servomotors, drivers and batteries, helping to reduce the exploitation of new raw materials.

Thus, the demand for manufacturing new equipment falls, the useful life of objects is increased, and waste is reduced. According to the United Nations Environment Programme, about 50 million tons of electronic waste is generated each year, and most of it does not go through an environmentally optimal recycling system. At Servo Motors Adjust we want to help reduce this problem.

Our goal is to continue advancing day by day in the IoT and implementing systems that respond to an industry 4.0. In this sense, the data show that the most digital industries are also more energy efficient.

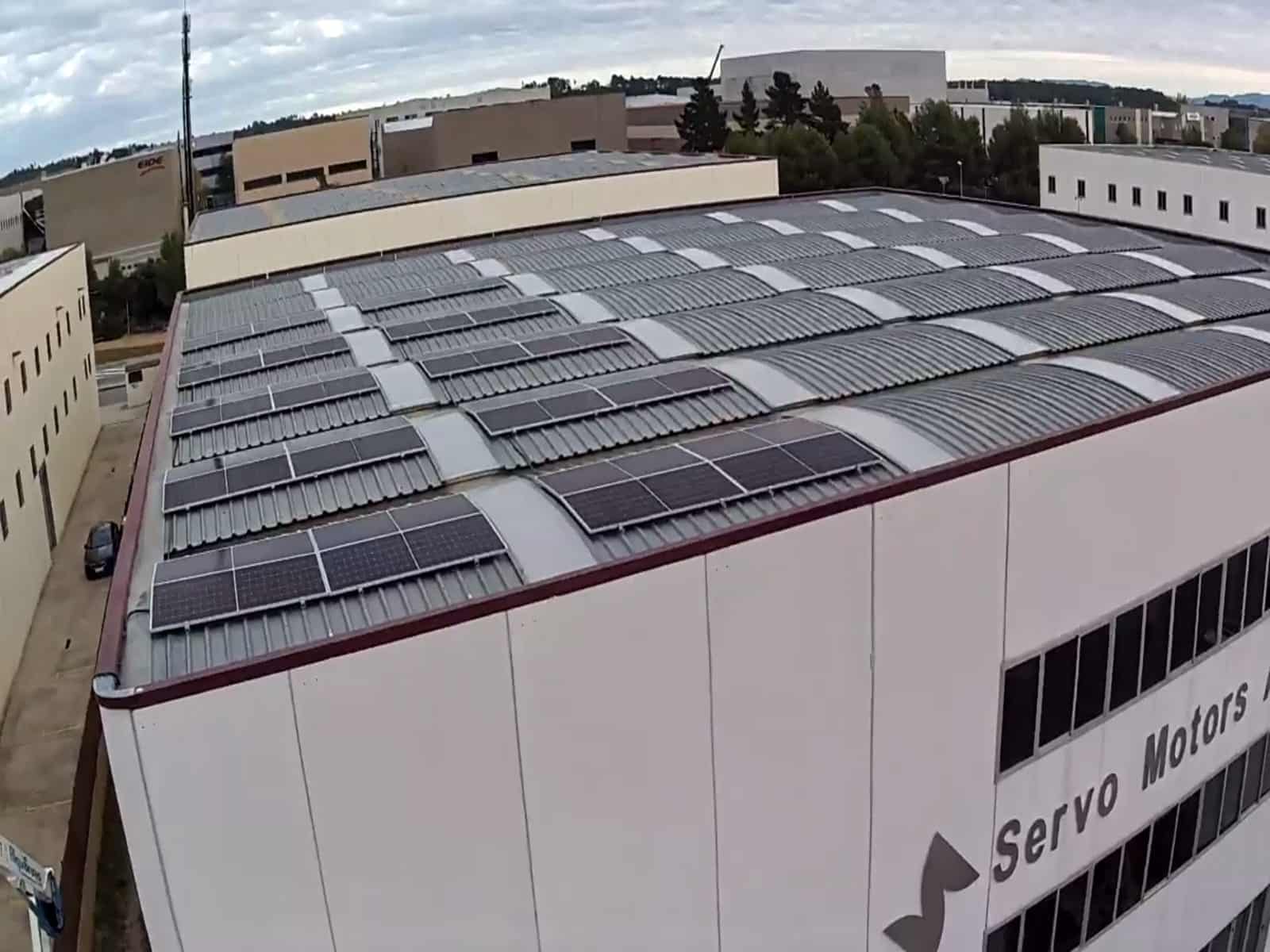

In addition, we carry out internal actions that allow us to be more sustainable in different areas. For example, we have installed photovoltaic solar panels that let us be energetically self-sufficient.

These panels, among other things, are used to charge the electric cars we have, to help reduce the carbon footprint that comes from transportation. They are our most recent projects, but for sure they won’t be the last. We love challenges!