THE IMPORTANCE OF PREVENTIVE MAINTENANCE FOR SERVOMOTORS

In the industrial world, servo motors play a crucial role. However, like any other equipment, they are subject to wear and possible failure.

While it is tempting to wait until a problem arises to address it, prevention is always the best strategy.

In this article, we will explore three key reasons why preventive maintenance of servo motors is not only recommended, but essential.

Reasons to perform preventive servo motor maintenance:

1- Save time

Having to change a servomotor because of a breakdown involves an unexpected waste of time.

Not only does this waste the time of engineers who have to change the servomotor and cannot perform the tasks they had scheduled, but also the machine will have to be stopped while it is being repaired.

Performing preventive maintenance during scheduled stops will avoid production losses.

2- Save money

Preventive maintenance is accounted as an expense, and this is true, but it is necessary to look at the economic benefits obtained by preventing a breakdown.

Even if the company has spare motors, stopping a production line may be more expensive than performing preventive maintenance.

3- Know if the servomotor works properly.

If any part is in poor condition due to improper working conditions of the servomotor, it will be detected during the motor’s preventive maintenance. This will allow us to reinstall the checked servomotor in the proper shape, if the motor works in optimal conditions, breakdowns will be prevented.

What is done to the servomotor during preventive maintenance?

During the preventive maintenance the general condition of the equipment is checked, as well as that of each of its components. This allows us to repair or replace worn or in poor condition parts due to the working conditions of the servomotor.

The servomotor’s mechanical, electrical and electronic components are tested and checked to be abale to change or repair them if necessary.

Preventive maintenance can prevent:

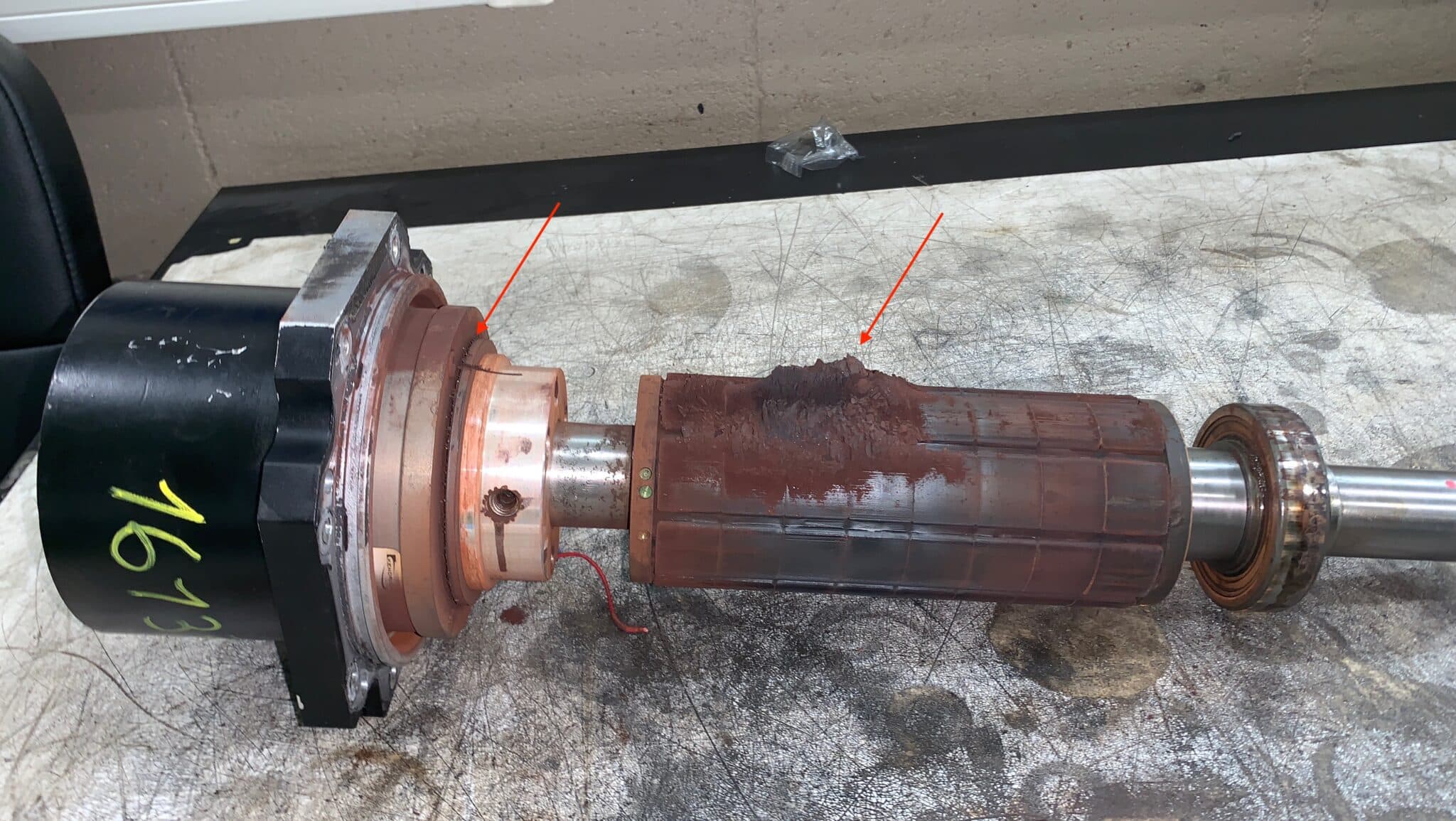

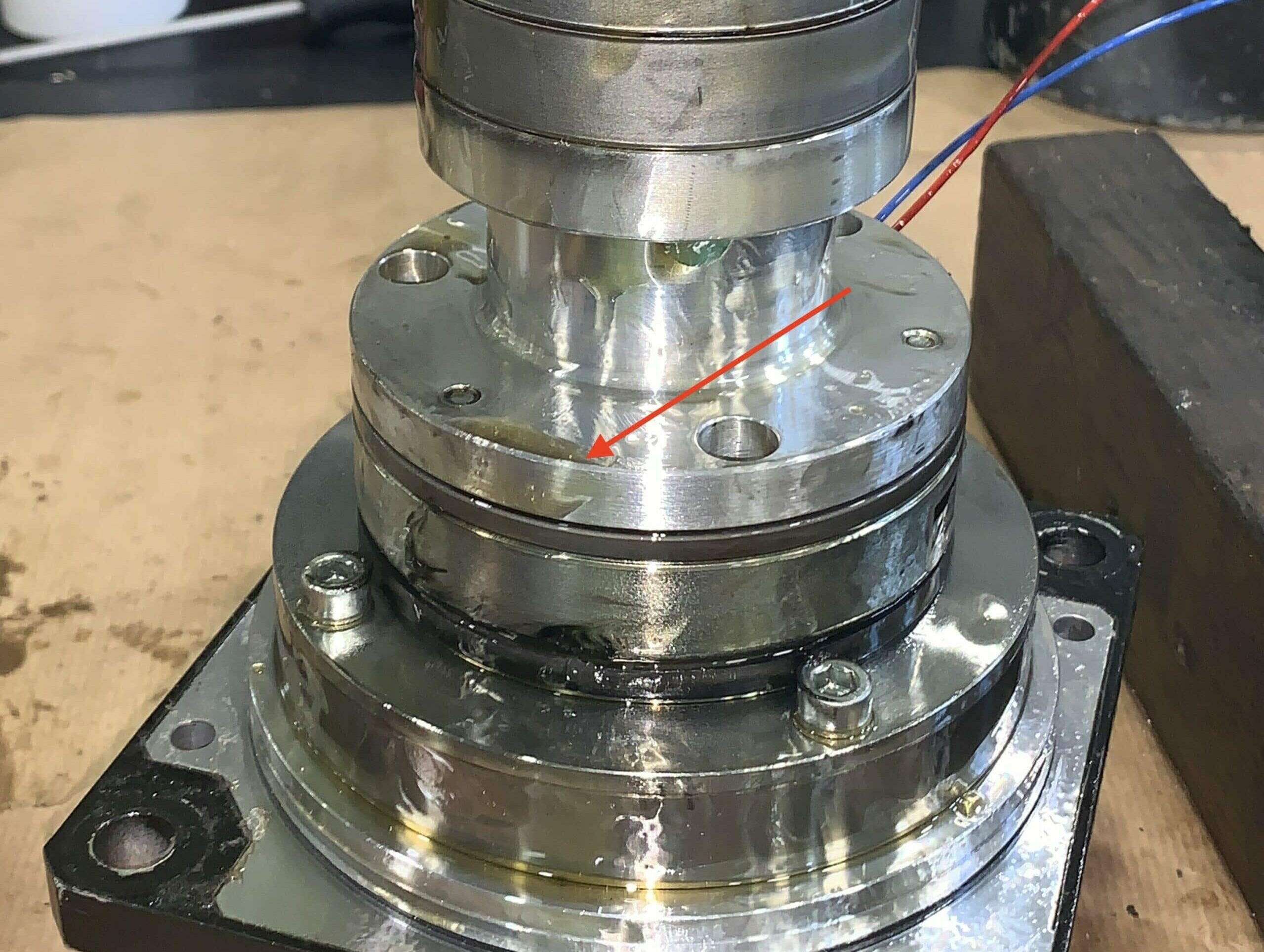

- Oil / water entry in to the servomotor. Sometimes motors are flooded with oil or water because the oil seal has dried and cracked, ceasing to fulfill its function.

- With proper maintenance the poor condition of the oil seal is detected in its initial stages, so it can be changed and prevent it from causing a breakdown.

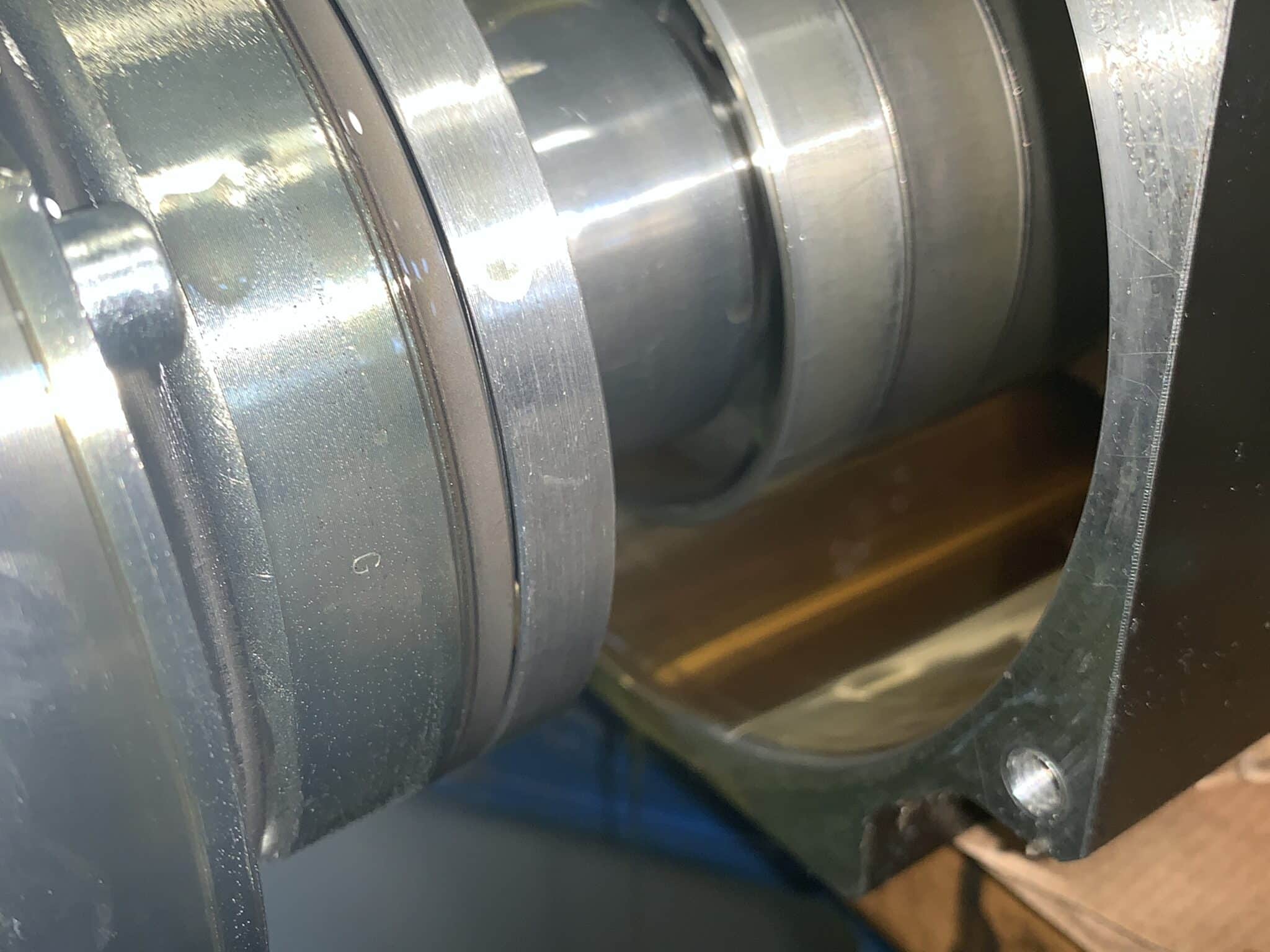

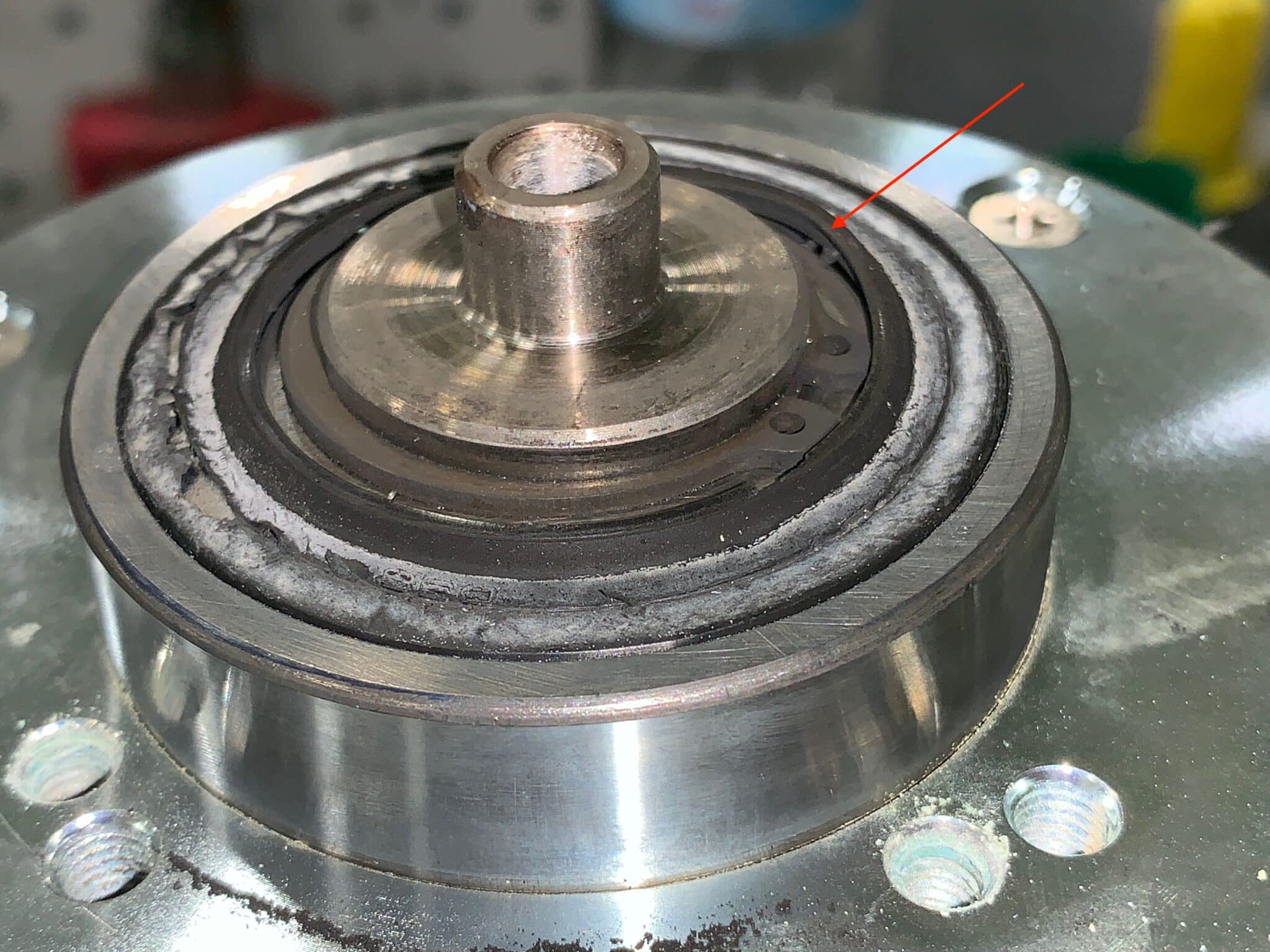

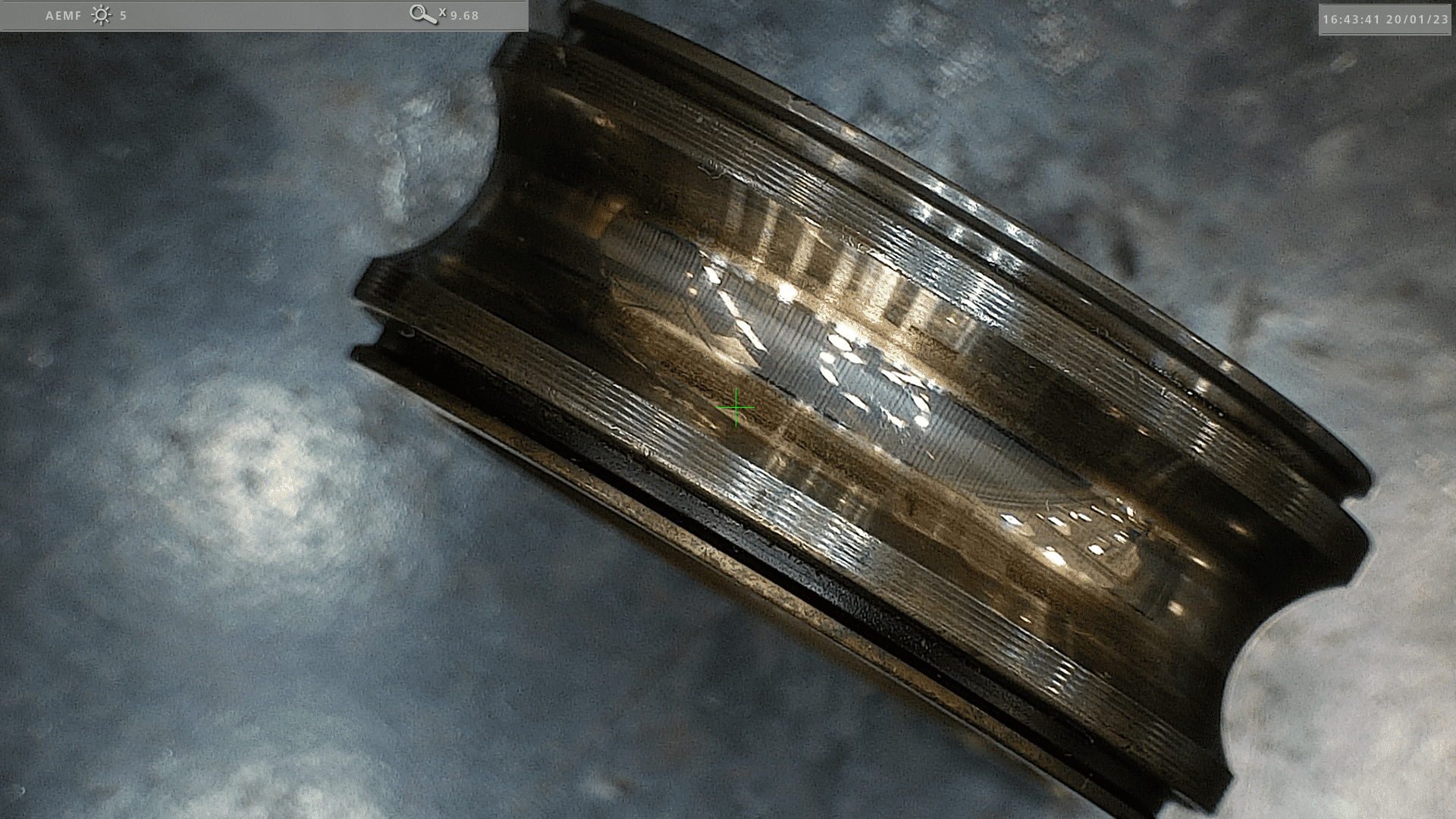

Bearing breakage. One of the parts that needs more maintenance are bearings, since they suffer a lot of wear and tear with the servomotor’s working.

When performing preventive maintenance, bearings are replaced, thus preventing them from breaking due to wear. Bearing breakage can cause severe servomotor breakdowns with high repair costs, such as winding or feedback failures.

Shaft breakage. Sometimes the shaft works in a forced position. This can cause it to twist and even break.

Brake failure. If preventive maintenance is not performed regularly, the servomotor’s brake can block and produce metallic dust.

Servomotor brakes may become defective after overheating. This would significantly increase the servomotor’s repair and service cost.

Loss of braking. When oil gets into the mechanical parts this affects its correct performance. This causes the a loss of Nm in the brake and may cause severe material damage.

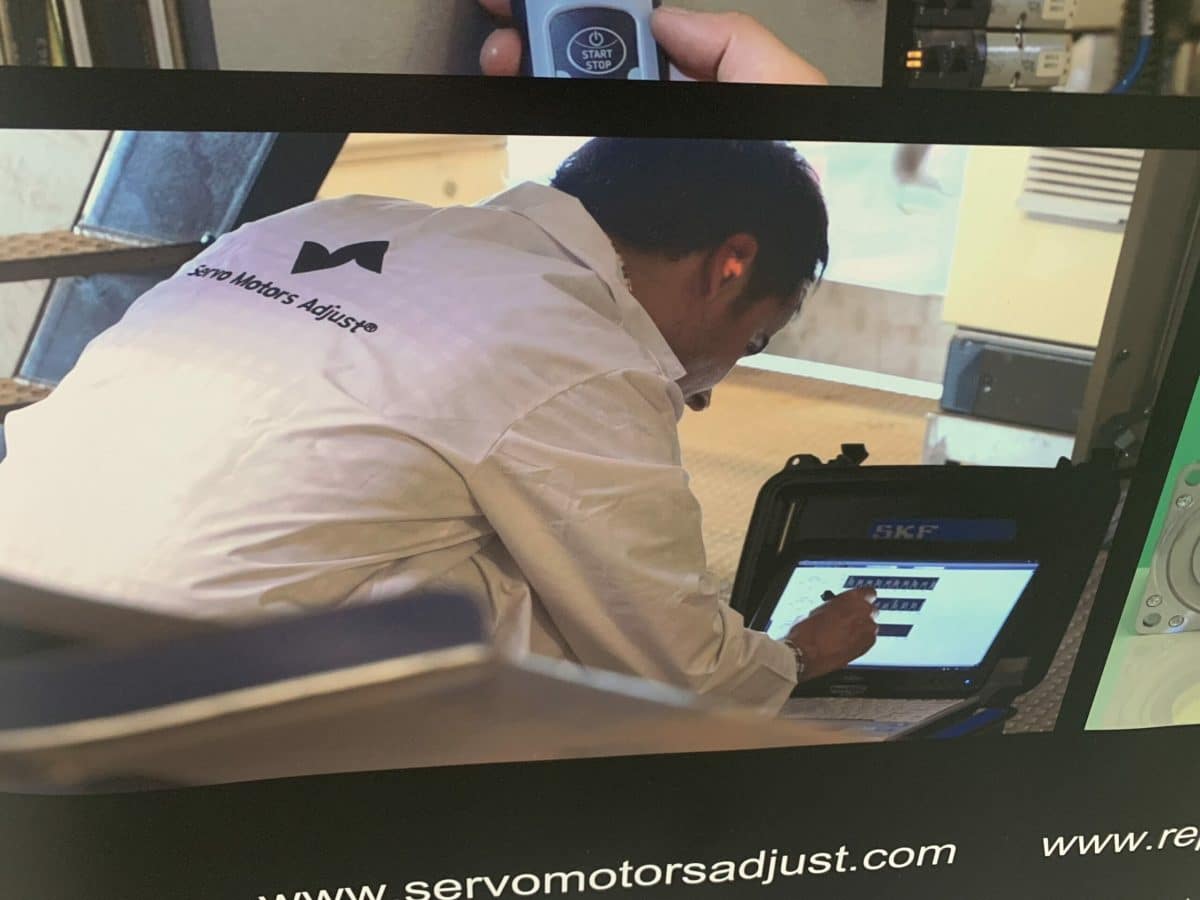

It is important to carry out preventive maintenance and especially to perform it in workshops that offer guarantees of quality service since it is not only necessary to have the appropriate equipment to perform the inspection and verification of the servomotor, but it is also essential to have deep knowledge of the different servomotor brands and models on the market.

YOU MIGHT BE INTERESTED IN: