We use the best and latest technology in servomotor maintenance.

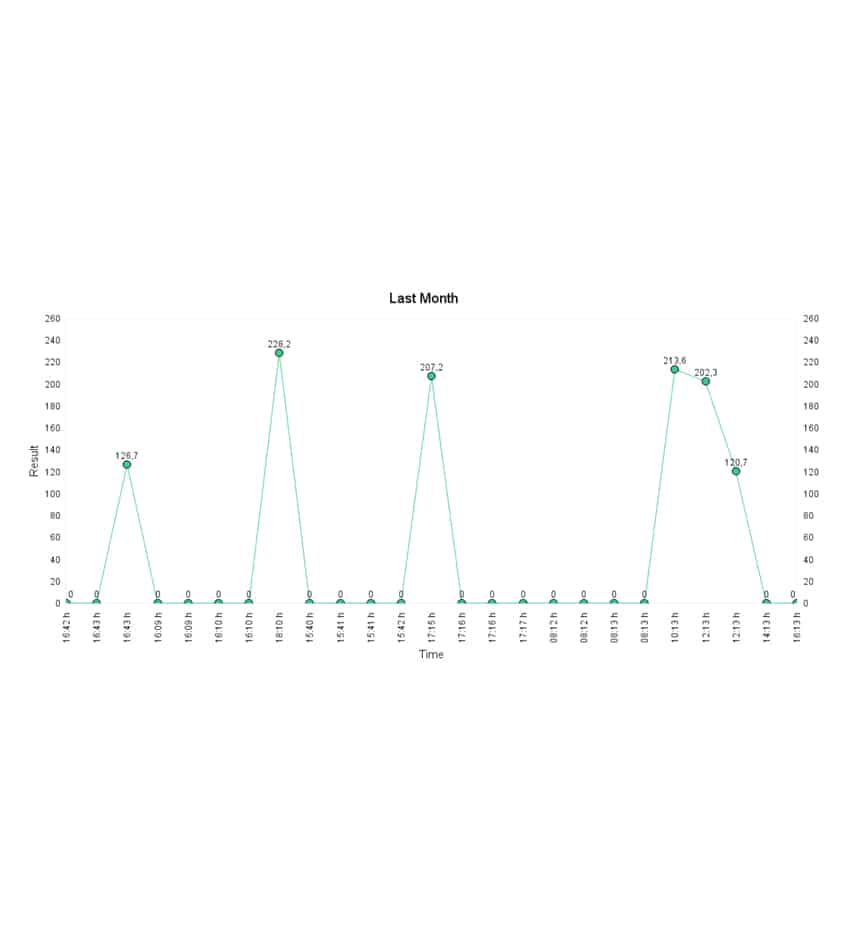

Our R&D department advances hand in hand with the 4th Industrial Revolution in machine learning in wireless sensors. Discover our new service: Predictive maintenance in real time!

Maintenance allows us to control and predict the reliability of the servo system.

Production stoppages have a high cost for companies.

It is essential to perform maintenance that optimizes the operation of the servo system and that is able to predict reliability in their usual working conditions.

Preventive maintenance of servomotors

This is where the components of the equipment are periodically replaced based on the study of the behaviour of each component. This technique focuses on the service life of each component over time, regardless of the cause of the fault.

Predictive maintenance of servomotors

This is maintenance based on time intervals, i.e. the analysis of the status of the system allows us to schedule interventions at the most appropriate time and anticipate possible failures before they happen.

Advantages

- Reduction of causal breakdowns.

- Reduced downtime.

- More efficient than reactive maintenance.

Status monitoring

This maintenance is based on the status of the servo system, in which we monitor a parameter of that system to detect significant changes that may indicate an immediate or future failure.

Advantages

- Early detection of faults.

- Carrying out maintenance only when necessary and in a planned manner.

- Breakdowns and production stoppages are avoided.

RCM

Reliability Centre Maintenance improves the knowledge of the motor’s status. Depending on this information the frequency of the service can change, reducing or increasing it, optimizing diagnostic costs and eradicating or minimizing downtime caused by breakdowns.

Advantages

- Early detection of faults.

- Elimination of the cause or origin of the failure.

- Carrying out maintenance only when necessary and in a planned manner.

- Breakdowns and production stoppages are avoided.

Do you want to know what kind of maintenance you need?

Why should you trust Servo Motors Adjust for servo motor maintenance?

99% repairs success rate

24-48 hour repair service

We only work with OEM parts (*Original Equipment Manufacturer)

Frequently asked questions about our servomotor maintenance service

Preventive maintenance for servomotors involves performing regular inspections and adjustments to ensure the equipment operates optimally for as long as possible. This type of maintenance focuses on the early detection of potential issues through activities like cleaning components, lubricating moving parts, and checking electrical and mechanical connections. By preventing wear or damage before it happens, preventive maintenance helps to ensure consistent performance and reduces the need for unexpected repairs.

The main benefit of preventive maintenance is the avoidance of unexpected failures, which helps prevent disruptions in the operation of the servomotor. Additionally, this type of maintenance helps extend the equipment’s lifespan by keeping it in optimal working condition. It is also an effective way to maintain the servomotor’s efficiency, as a well-maintained motor tends to operate with greater precision and stability, preventing premature wear of critical components.

Predictive maintenance is a more advanced approach that relies on continuous monitoring of the servomotor’s condition. Using sensors and advanced technologies, such as vibration analysis or temperature monitoring, data is collected in real-time about the motor’s status. From this data, early signs of potential faults or irregularities can be identified, allowing corrective measures to be taken before serious problems arise. This methodology is ideal for optimizing performance and reducing risks.

Predictive maintenance is crucial because it offers the ability to anticipate problems, avoiding unplanned downtime that can be costly and disruptive. By identifying emerging issues through constant monitoring, the appropriate intervention can be scheduled at the right time, reducing both downtime and repair costs. Additionally, this approach promotes more efficient use of resources and helps improve the overall reliability of the system.

The frequency of preventive maintenance varies depending on the characteristics of the servomotor, the environment in which it operates, and the level of use. However, the most important aspect is to adopt a regular strategy that ensures the equipment remains in good condition. The key is not to wait for visible signs of wear or malfunction but to act proactively to ensure long-lasting and reliable performance.