Servomotor and AC/DC motor repairs

Our servomotor repair process is based on two premises: efficiency and quality.

We get your production lines back up and running at full capacity in the shortest possible time.

In addition, for special products, we have spare motors and drivers available to reduce downtime.

Our servomotor and AC/DC motor repair process

- Customer identification

- Reference number

- Type of repair: normal, urgent…

- Photographic report

- Data registration, resistance, insulation…

- Identification of the cables

- Mechanical configuration

- Photographs

- Voltage generator/ Phases / Equilibrium

- Switching (encoder, resolver)

- Tachometer and phase outputs

- Auxiliary equipment (encoder, resolver)

- Operational test

- Bearings, shafts, bearing housings, seals.

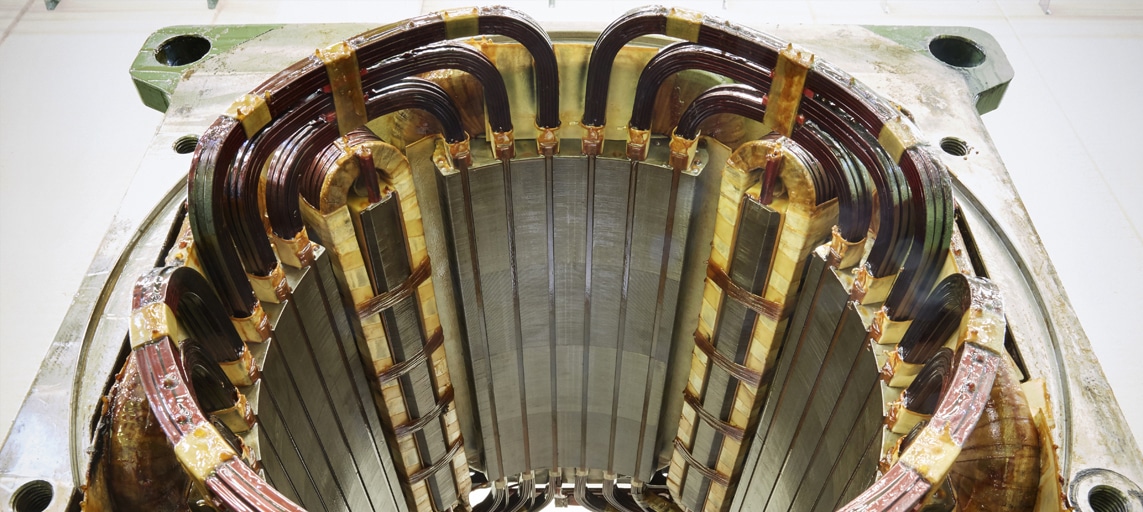

- Windings

- Magnetic field

- Brakes

- Encoder / Resolver / Tachometer

- Quality dimensional controls

- Resistance and high voltage test

- Preparing an offer

- Stator Rewind

- Data collection

- Connections

- Testing of the new winding

- Mechanical tolerances

- Brakes

- Encoder / resolver / Tachometer alignment

- Hall effect

- Test/verification on test bench

- Taking data, resistance, insulation

- Photographic report

- Suitable packaging

- Customer notification of the shipment

We repair all brands of servomotors

Schneider Electric – Elau

Lenze

Sew

Parker

ABB

Fanuc

Siemens

Tamagawa

Elmo

Control Techniques

Allen Bradley

Bosch Rexroth – Indrama

Baumuller

B&R

Danaher Motion

Kollmorgen

Pacific Scientific

Mavilor

Magnetic

Stober

Vickers

Emhart Glass

Parvex

Lafert

Kuka

Mitsubishi

Moog

Keb

Bag

Heidenhain

Cincinnati Milacrom

Electrocraft

Omron